Individual gripper solutions

The “heart” of all automation solutions is the gripper technology.

The “heart” of all automation solutions is the gripper technology.

It is essential that workpieces are handled quickly, reliably and above all, gently, so that they are placed damage-free in the workpiece carrier.

FLG manufactures and supplies vacuum grippers through to complex multiple gripper systems with grid point configuration.

When faced with new challenges, our engineers can fall back on our many years of experience in the field of automation and our huge range of applications.

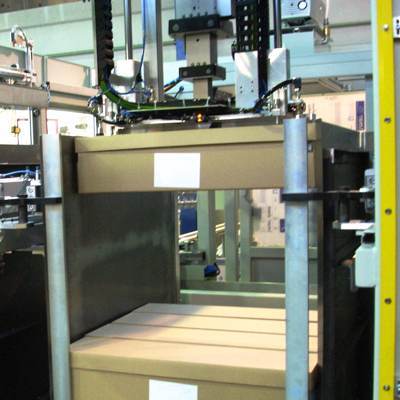

Vacuum gripper for telescope-type boxes

Vacuum suction gripper system for depalletizing of telescope-type boxes. The cartons are taken suckers side bellows means wrinkles.

Vacuum suction gripper system for depalletizing of telescope-type boxes. The cartons are taken suckers side bellows means wrinkles.

Inside the gripper there is integrated an automatic position identification system of the packages on the pallet.

Standard Tray gripper

The figure shows a blend gripping system for plastic trays. The trays are added to the side of the contour.

The figure shows a blend gripping system for plastic trays. The trays are added to the side of the contour.

The gripper systems are equipped with a level switch.

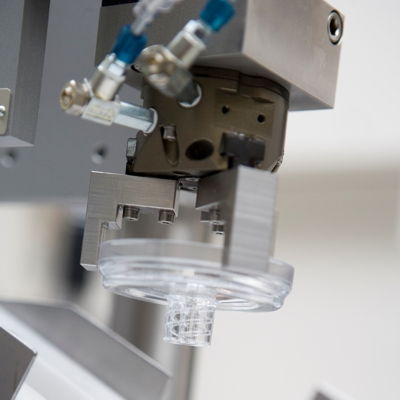

Clamp gripper for memory module

Gripper jaws for memory modules. The gripper takes the memory sticks from a twin-belt conveyor and places them in a special plastic tray. The rotating arm then turns them through 90° and places them in an upright position.

Gripper jaws for memory modules. The gripper takes the memory sticks from a twin-belt conveyor and places them in a special plastic tray. The rotating arm then turns them through 90° and places them in an upright position.

Grippers for cartridges in the pharmaceutical sector

12-fold removal of cartridges from a discontinuous belt, which are then placed, individually packed, in aluminum trays. Capacity: approx. 4,800 cartridges per hour.

12-fold removal of cartridges from a discontinuous belt, which are then placed, individually packed, in aluminum trays. Capacity: approx. 4,800 cartridges per hour.

Multiple vacuum suction gripper

15x vacuum gripper system for removal of products from a carton.

15x vacuum gripper system for removal of products from a carton.

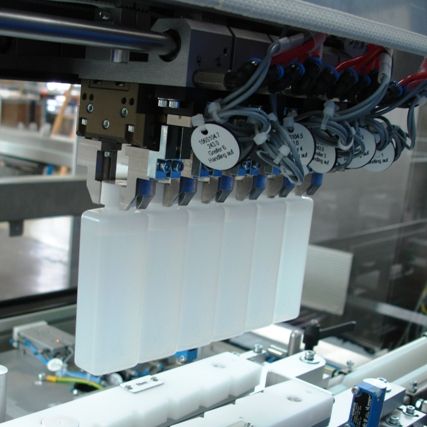

Multiple grippers for cartridges in the pharmaceutical sector

12x removal of cartridges from cycle belt with subsequent individual packaging in aluminum trays. Power about 4,800 cartridges per hour.

12x removal of cartridges from cycle belt with subsequent individual packaging in aluminum trays. Power about 4,800 cartridges per hour.

Expander gripper system for glass bulbs

10-fold expander gripper system for glass bulbs. The system compensates for fluctuating distances between the feeding technology and the load carriers.

10-fold expander gripper system for glass bulbs. The system compensates for fluctuating distances between the feeding technology and the load carriers.

Multiple vacuum gripper system for up to 10 glass bulbs.

Clamping gripper for 40 kg trays

Gripper jaw system for handling 40 kg trays with sensor rod for scanning the loading height and position alignment.

Gripper jaw system for handling 40 kg trays with sensor rod for scanning the loading height and position alignment.

ABS components

Finger gripper system for the depalletizing of valve stacks for the production of ABS components.

Finger gripper system for the depalletizing of valve stacks for the production of ABS components.

Multiple gripping system for plastic bottle

The gripper system is designed for 6 different formats and sizes of plastic bottles. With a servo motor drive the grippers are adapted according to the bottle formats on the tray cavity spacing.

The gripper system is designed for 6 different formats and sizes of plastic bottles. With a servo motor drive the grippers are adapted according to the bottle formats on the tray cavity spacing.

Robot gripper for equipping of tool carriers

Multiple vacuum suction pads for mounting of workpiece carriers with brushes. The products are delivered via palletizer in trays, were taken by robots and placed in the WT.

Multiple vacuum suction pads for mounting of workpiece carriers with brushes. The products are delivered via palletizer in trays, were taken by robots and placed in the WT.