APACS: radiation under control

APACS: an efficient automation system for the shipment of radiopharmaceuticals.

In close consultation with the customer FLG Automation AG realized the completely new and innovative logistics concept APACS (Automated Palletising and Consignment System) for order picking of radiopharmaceuticals for diagnostic imaging and radiotherapy in thyroid and tumor diseases.

The Task

The Task

In addition to reducing the already well below the statutory provisions limit values for the radiation exposure of staff, it was the logistics processes of the existing production and the flow of data to analyze the existing SAP system and redefine. The structurally specified premises at the customer required an extremely space-saving and thus low-tolerance storage of up to 1,400 packages of different dimensions. Conventional high-bay solutions dropped out due to the high for this type of application accuracy and limited space. In peak times, the system had to be able to simultaneously store about 500 packages per hour or outsource for shipment. However, the biggest challenge was the installation of the system on site. In only 56 hours, the interfaces to the existing IT systems had to be installed, tested and OQ (Operational Qualification) can be carried out, so the next working day there was a 100% functional and validated system available.

The Solution

The Solution

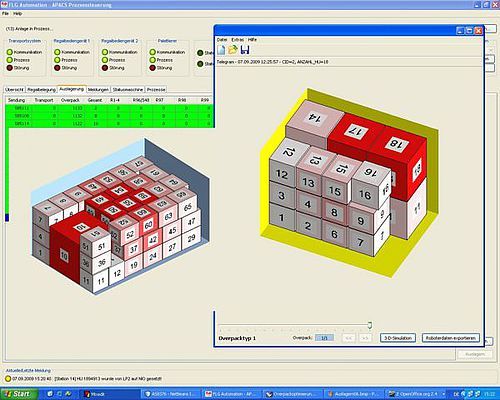

APACS is based on a high-bay warehouse-like storage / picking area in which two independently working stacker cranes loading and unloading packages in four rack systems. All package movements are recorded by a barcode scanner and he is saving the position of the package in the shipping area in a database. The shipping orders will receive APACS by the superordinate SAP system and supports distributed on several pallets of packages. Before outsourcing and packing the packing pattern of the individual pallets are calculated by an integrated pack pattern generator.

The software converts the data for optimal shipping packing patterns that take into account in addition to an optimal space utilization of the transport boxes and the different radiation intensity. This is necessary so that the radioactive radiation of the picked pallets / shipping cartons remains below the statutory limits.