Automated assembly components for new eco-friendly engine generations.

Complex testing and assembly technology.

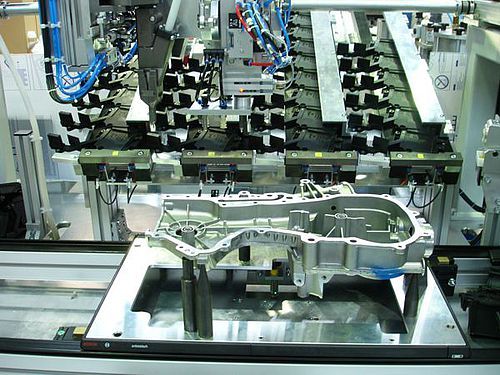

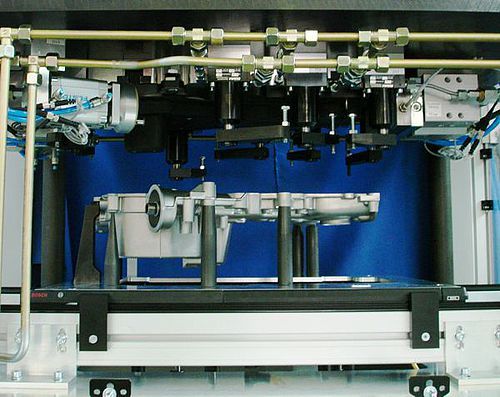

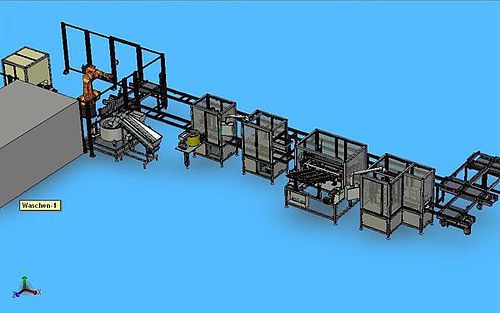

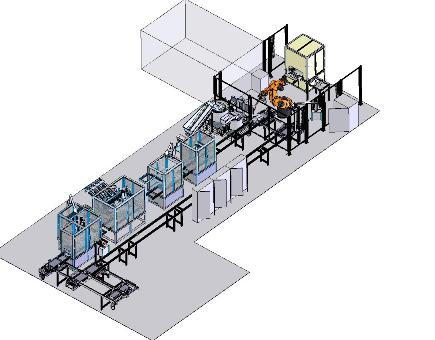

For the manufacture of a motor subassembly the FLG Automation AG has developed and implemented a complete assembly line. On it the control housing for new motor series of eco-friendly mid size cars are fully automatically assembled and tested.

In the foreground of interpretation in addition to the high quality requirements of the automotive manufacturer were complete traceability of manufactured components and high process reliability. All costs incurred in the line assembly and test results are the single control unit via an RFID chip in the workpiece carrier of the transport system, the Data Matrix code of the control housing, assigned and stored after completing the operation in a database. A 6-axis robot from KUKA accepts the removal of the case from the car wash and passes it to the first control station.

Here all machine contour surfaces are checked for possible voids inclusions using an intelligent image processing system. In the following assembly processes along the linear transfer system individual components force-displacement monitored are joined into the housing, oiled and glued airtight. Special dosing always give this amount precisely defined starting at the component. With electronic screwdrivers and various delivery systems further construction provided a hurry and screwed torque monitoring. Following the complete component is clamped in a specially developed hydraulic pressure checking system, sealed and the individual chambers are checked for leaks. Only now, after all components have been error-free, reliably assembled and tested, the way is clear for engine assembly.