Integration of individual assembly components

As a system provider, it goes without saying that we can also integrate add-on technologies in order to meet individual requirements in the assembly process.

As a system provider, it goes without saying that we can also integrate add-on technologies in order to meet individual requirements in the assembly process.

The open architecture of our turnkey systems allows integration of any number of supplementary processing steps. This is cost-effective for our customers when planning and designing customized solutions.

From image processing, labeling, checking, welding, screwing, control and packaging through to feeding, we are able to integrate virtually every conceivable assembly and handling process into our systems.

Machine vision

We integrate cutting edge camera systems in the assembly line for the purposes of visual quality control and position and presence monitoring. The scope of the implemented components depends on the application and includes optics, lighting and software for evaluation of the image information.

We integrate cutting edge camera systems in the assembly line for the purposes of visual quality control and position and presence monitoring. The scope of the implemented components depends on the application and includes optics, lighting and software for evaluation of the image information.

Screw technology

Using integrated screwing units, screwing tasks are executed reliably and with maximum repeat accuracy. The technology uses servomotors and compressed-air. Torques, screw-in depth and angle of rotation can be precision-set and stored.

Using integrated screwing units, screwing tasks are executed reliably and with maximum repeat accuracy. The technology uses servomotors and compressed-air. Torques, screw-in depth and angle of rotation can be precision-set and stored.

Welding engineering

As a sensitive and sophisticated technology, ultrasonic sealing is ideal for assembly/jointing tasks in the plastic sector. Prior to any integration of such technologies in the assembly process we hold in-depth discussions with our partners. We also offer additional welding technologies, such as laser and/or infrared welding.

As a sensitive and sophisticated technology, ultrasonic sealing is ideal for assembly/jointing tasks in the plastic sector. Prior to any integration of such technologies in the assembly process we hold in-depth discussions with our partners. We also offer additional welding technologies, such as laser and/or infrared welding.

Example:

Rotary indexing tables

Rotary indexing tables are often used if interlinked assembly processes need to be automated quickly and reliably.

Rotary indexing tables are often used if interlinked assembly processes need to be automated quickly and reliably.

Rotary indexing tables are the ideal compact solution for executing a series of complex assembly tasks where space is at a premium.

With our servo-driven rotary table assembly solutions, even heavy loads can be positioned dynamically and precisely in a minimum of space.

Example:

Feeding technology

For the feeding of individual components for further processing in assembly lines, we use the tried and tested conveying and separating technology made by our partner of many years. As well as our own palletizing systems, we also integrate spiral feeders, stepper feeders and drum feeders for smooth separation and orientation.

For the feeding of individual components for further processing in assembly lines, we use the tried and tested conveying and separating technology made by our partner of many years. As well as our own palletizing systems, we also integrate spiral feeders, stepper feeders and drum feeders for smooth separation and orientation.

Example:

Measuring and test technology

For the monitoring of individual assembly steps or complex assembly process, it is essential to perform checks on the respective assembly process.

For the monitoring of individual assembly steps or complex assembly process, it is essential to perform checks on the respective assembly process.

The implemented test procedures are selected according to the product or to customer specifications.

Whether leak test measurements, filling level controls, torque, or angle of rotation monitoring etc., we are able to integrate and evaluate all common methods of testing in our assembly concepts.

Example:

Packaging technology

And of course, if we are dealing with a completely automated production process, we mustn’t forget the packaging of the finished product. Our systems can also integrate machines for primary packaging, such as blisters, through to final packaging, such as stretch-wrap film packaging, to ensure the safety of the load on dispatch pallets.

And of course, if we are dealing with a completely automated production process, we mustn’t forget the packaging of the finished product. Our systems can also integrate machines for primary packaging, such as blisters, through to final packaging, such as stretch-wrap film packaging, to ensure the safety of the load on dispatch pallets.

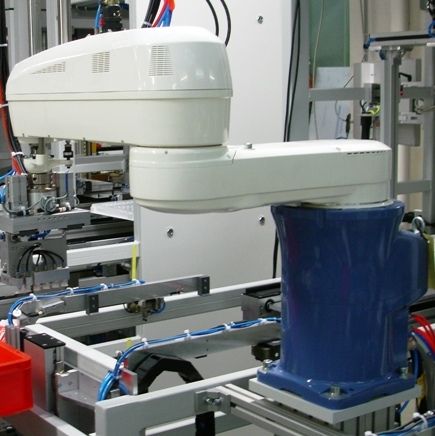

Robotics

In addition to our handling systems we integrate naturally also robot technology in our assembly plants. Depending on the task, we fall back on SCARA or 6-axis systems system of different suppliers.

In addition to our handling systems we integrate naturally also robot technology in our assembly plants. Depending on the task, we fall back on SCARA or 6-axis systems system of different suppliers.

… and so much more!